comprehensive engineered solutions

Sanitary / Wash Systems

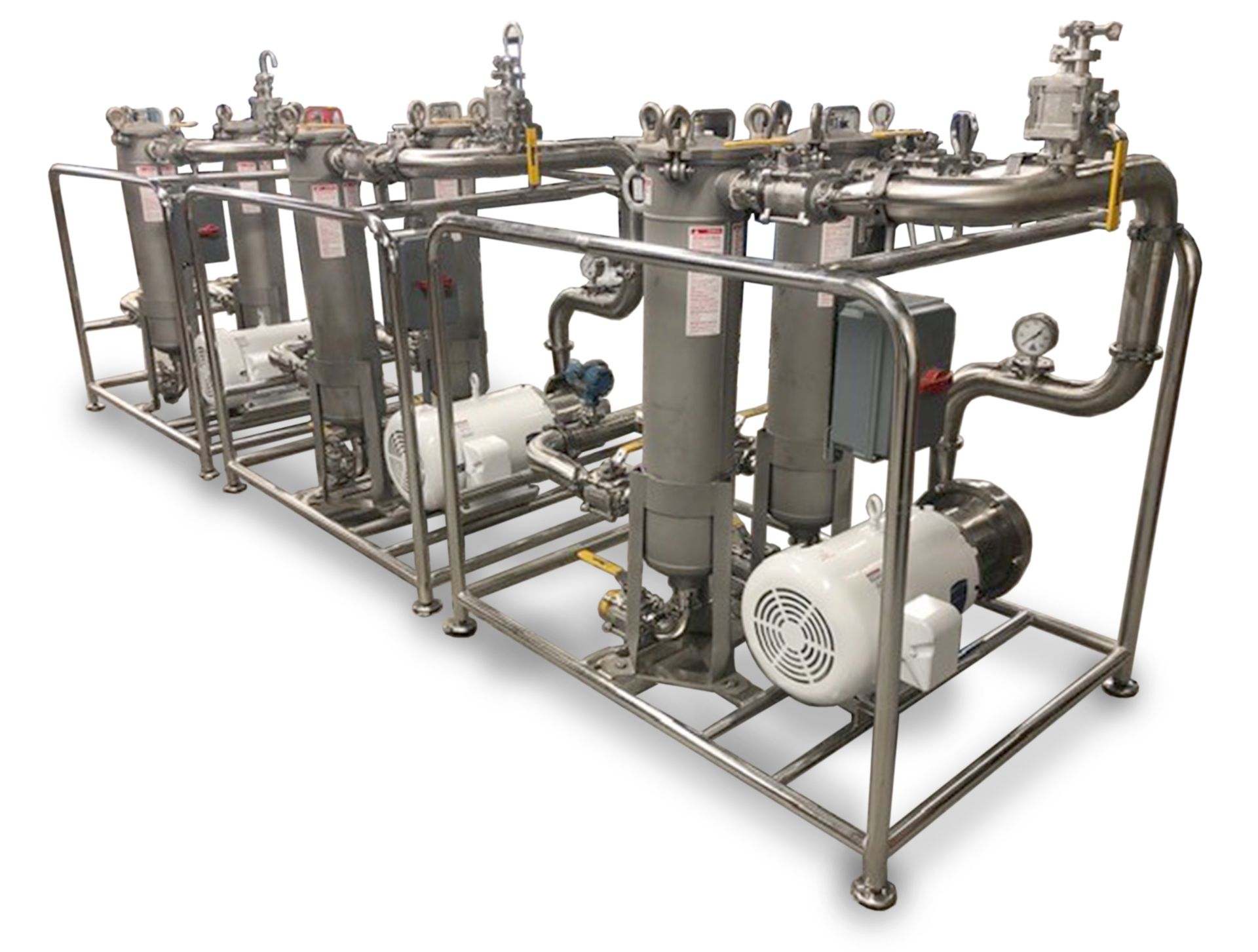

Our Sanitary / Wash Systems provide efficient and automated cleaning solutions designed to ensure thorough sanitation, reduce downtime, and maintain the highest hygiene standards in food processing facilities.

Sanitary Pumps, Control Valves, and process design

We can provide a range of sanitary pumps, control valves, and complete system engineering to meet the stringent hygiene requirements of the food processing industry. These components ensure reliable and efficient operation, providing precise control over your processing operation or CIP sanitation processes.

Key Features

Hygienic design for easy cleaning

Reliable and efficient performance

Precise control

CIP Tanks

Our Clean-in-Place (CIP) Tanks are essential for automated cleaning of your processing equipment without disassembly. These tanks are designed to deliver effective and consistent cleaning, reducing downtime and ensuring thorough sanitation.

Key Features

Efficient automated cleaning

Reduced downtime

Consistent and thorough sanitation

Sanitary Piping

Sanitary piping is a critical component of our wash systems, ensuring the safe and efficient transport of food products or cleaning solutions throughout your facility. Our sanitary piping solutions are designed to meet the highest standards of hygiene, preventing contamination and ensuring consistent cleaning performance.

Key Features

3D Engineered drawings

Shop built or field installed systems

Easy to clean and maintain

CIP Headers and Zoned Wash Systems

Our CIP Headers and Zoned Wash Systems are designed to deliver targeted cleaning to specific areas of your processing equipment. These systems ensure that every part of your equipment receives the appropriate level of cleaning, enhancing overall sanitation and efficiency.

Key Features

Targeted cleaning for specific areas

Enhanced sanitation and efficiency

Customizable cleaning zones

Reach Out to Us →

Ready to optimize your production process with our engineered solutions and automation services? Contact us today to learn more about how we can help you achieve your operational goals and improve efficiency.