comprehensive engineered solutions

Cryovac Support Equipment

Our Cryovac infeed and discharge equipment reduces rework, minimizes leakers, and increases productivity and is designed to meet the demanding needs of food processing facilities, providing efficient and reliable solutions for packaging and preserving products. Our equipment range includes shrinkers, drench cabinet shrinkers, hot water cascade systems, cold water chilling systems, and blow-off cabinets. Augmented by servo or induction motor infeed systems and pack stations, these solutions can ensure you optimize your ROI from your Cryovac packaging machine.

Shrinker

Our shrinkers utilize advanced technology to provide superior shrink packaging, ensuring tight and secure wrapping of products. This enhances product presentation and extends shelf life.

At a glance: Shrinker

| Technology | Reliability |

|---|---|

| Consistent shrink from engineered water distribution | Serviceable and removable conveyor |

| Sanitary heat shields provide: | Open water cascade with height adjustment |

| Lower energy costs; can save up to $16,000 per year | Water pump/motor slides out for safe, fast service |

| Lower exterior temps by over 60 F | Duct work available with inspection ports |

KEY FEATURES

Drench Cabinet Conveyor

Ensures even and consistent shrink wrapping by drenching products with hot water, achieving a perfect fit every time.

Hot Water Cascade System

Utilizes a cascade of hot water to evenly shrink wrap products, ensuring uniformity and reducing packaging defects.

Chiller

Our chillers are designed to quickly and efficiently cool products, maintaining freshness and extending shelf life. The cold water chill system ensures rapid temperature reduction, ideal for preserving the quality of perishable items.

At a glance: Chiller

| Technology | Reliability |

|---|---|

| PlC with color HMI for precise temperature control | Toolless teardown and set up |

| Self-contained cooling system that does not reject heat into your refrigerated room | Stock components |

| Quick, efficient cooling of product for improved shelf life and food safety | On-site and remote support available |

KEY FEATURES

Cold Water Chill System

Provides rapid and consistent cooling, ensuring products reach the desired temperature quickly to maintain freshness and safety.

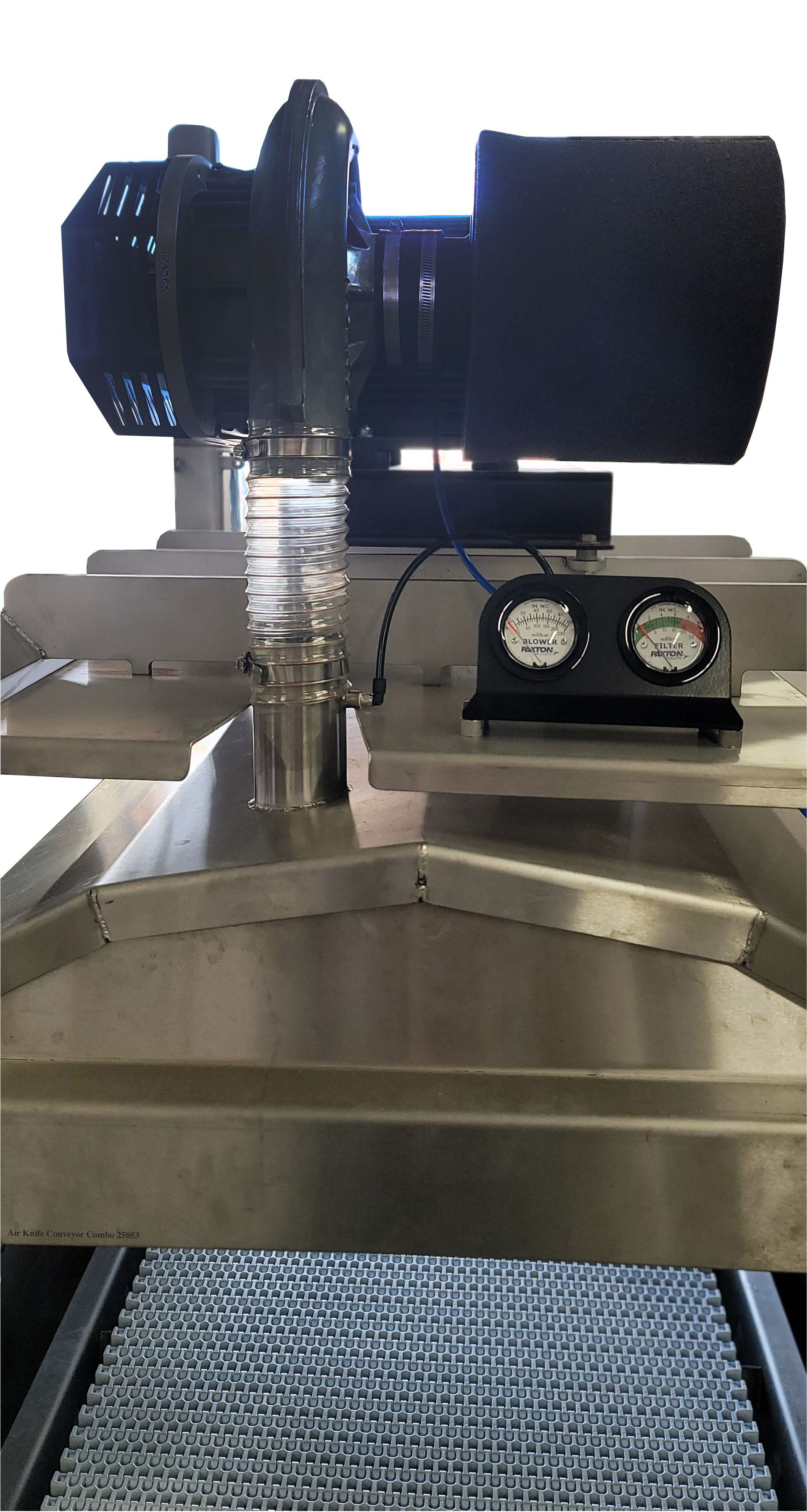

Blow-Off Cabinet

Our blow-off cabinets are equipped with high-performance blowers to effectively remove excess water from products after the shrink and chill processes, ensuring they are dry and ready for packaging.

At a glance: Blow-Off Cabinet

| Technology | Reliability |

|---|---|

| Toolless adjustment of the airknife height | Components selected to minimize maintenance |

| UL control cabinet can also operate the shrinker and chill cabinet | Full Bill of Materials prior to shipment |

| Blowers from 3 horse to 7/12 hp | Available in 316 stainless |

| Blowers can be mounted above or below the conveyor belt as elevations allow | All custom lengths and widths available |

KEY FEATURES

Paxton PX1000 Blowers

High-efficiency blowers that provide powerful air flow to remove water from products quickly and effectively.

Sonic Blowers

Deliver strong and consistent air flow for efficient water removal, ensuring products are dry and ready for further processing or packaging.

Spencer Regenerative Blowers

Offer reliable and continuous air flow, designed to handle high volumes and ensure thorough drying of products.

Reach Out to Us →

Our Cryovac equipment is engineered to enhance your food processing operations, ensuring efficient, reliable, and high-quality packaging solutions. Contact us today to learn more about how our Cryovac equipment can optimize your packaging and preservation