comprehensive engineered solutions

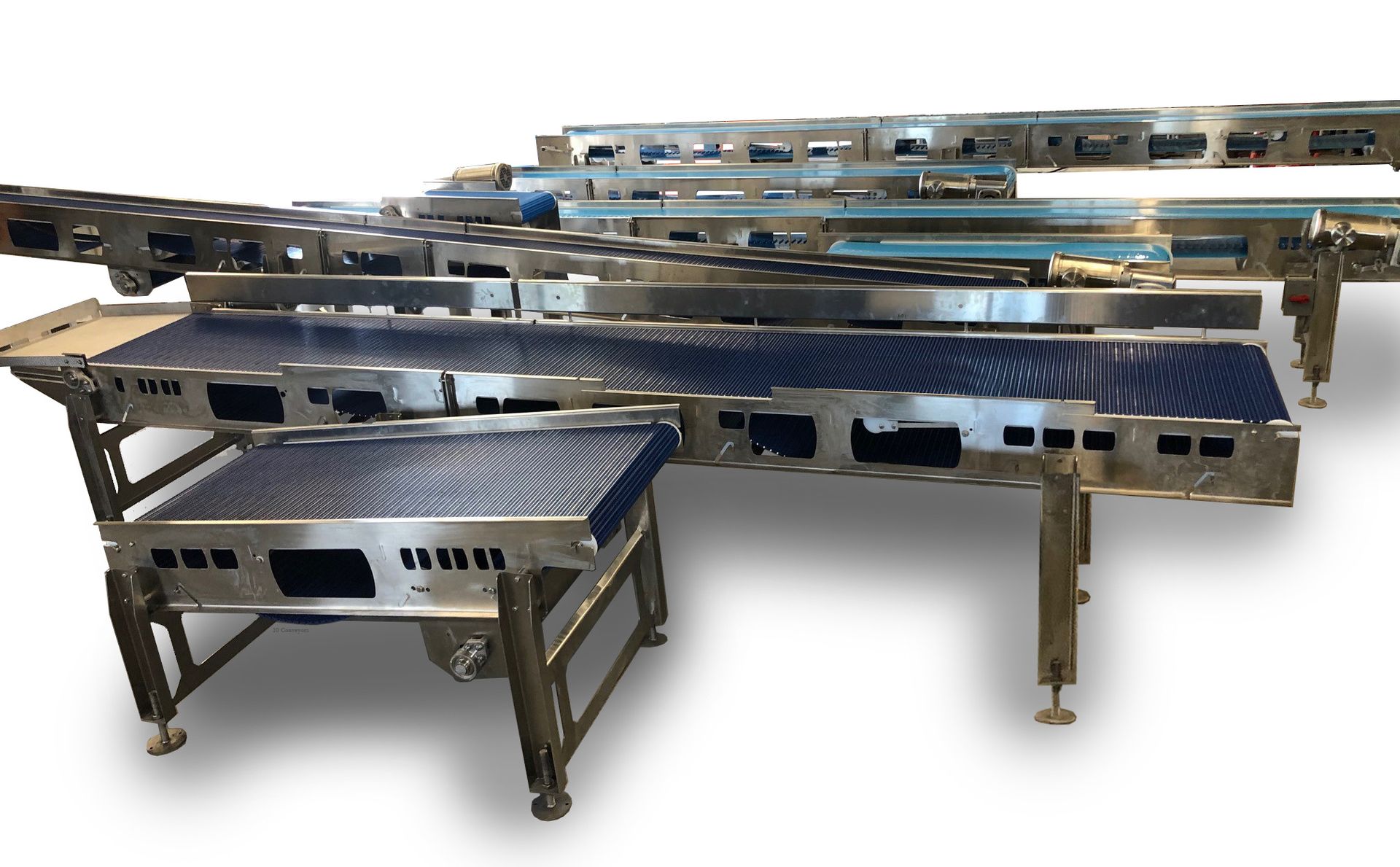

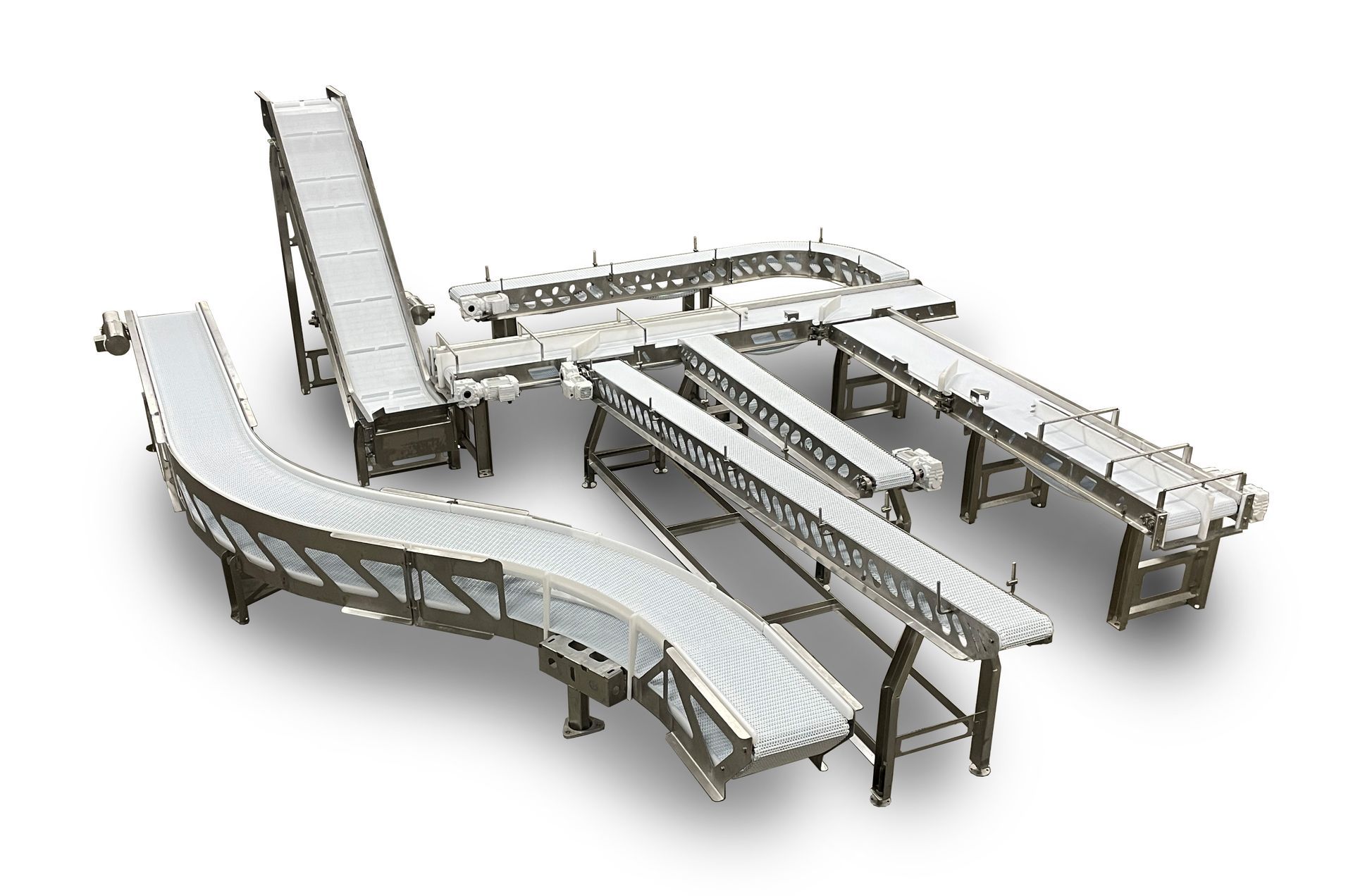

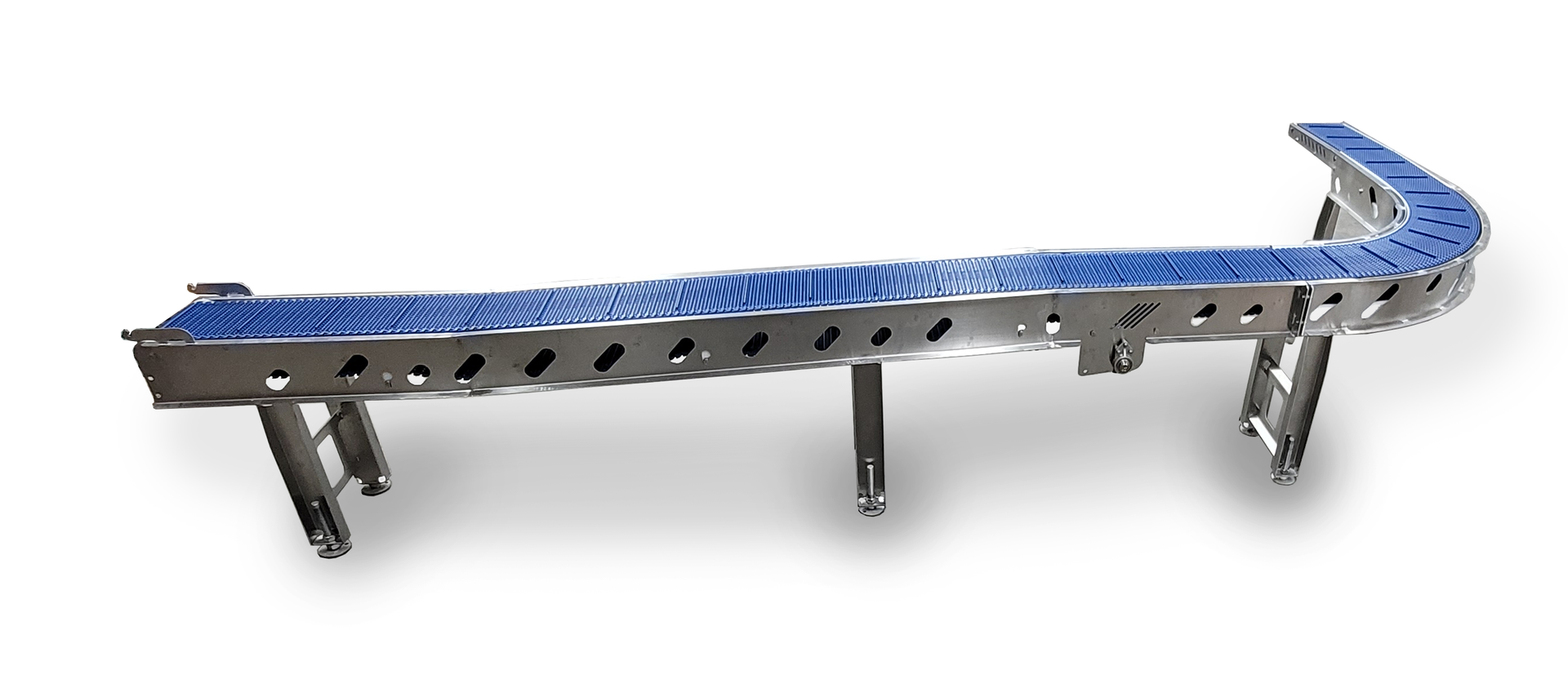

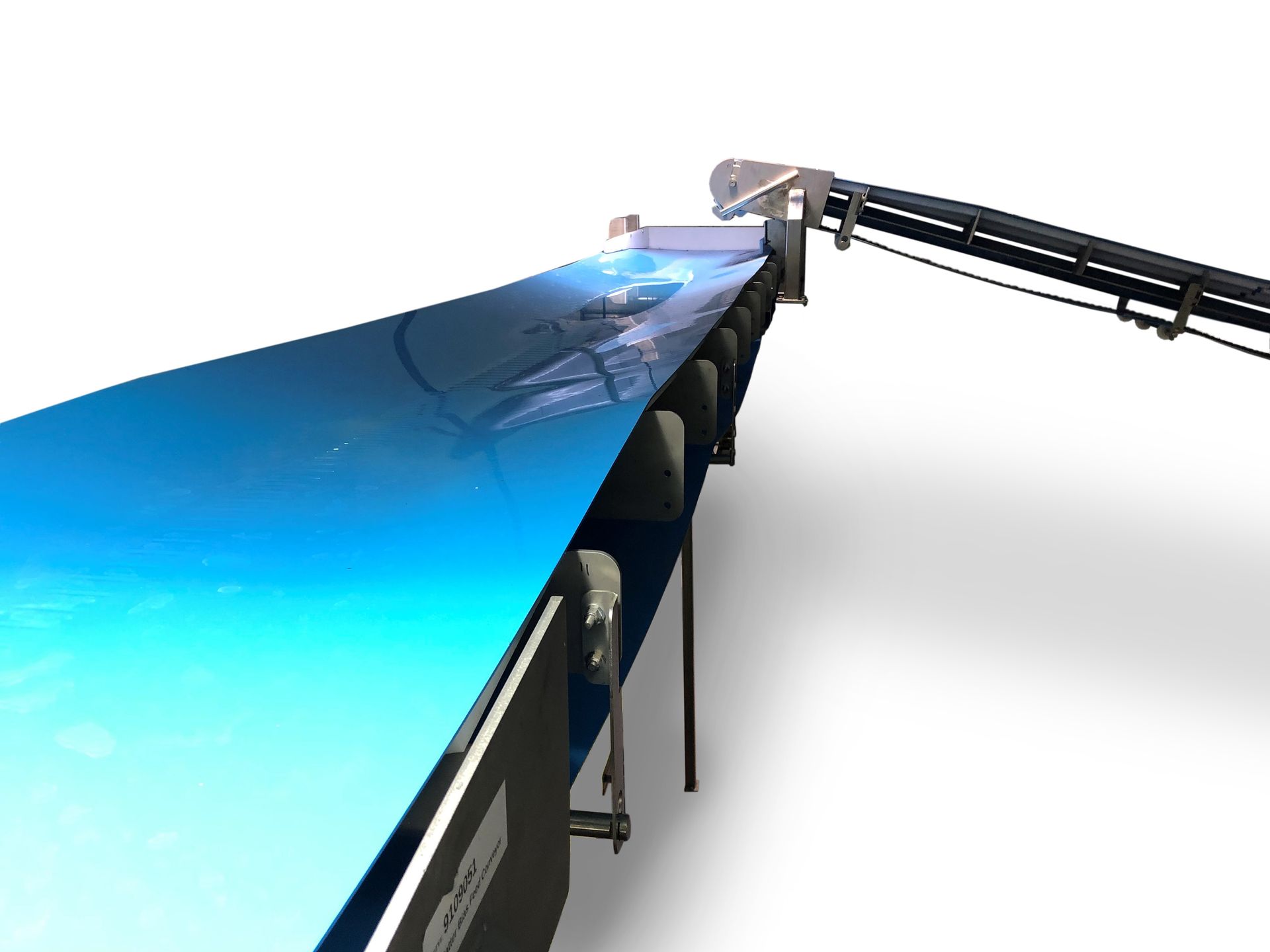

Custom Conveyors

Tabletop Conveyors

Our custom tabletop conveyors are designed on the premise of both people safety and food safety. With a focus on operational ease, we incorporate strategically placed sidewall cutouts for easy cleaning and maintenance access, while ensuring compliance with food safety regulations.

At a glance: Tabletop Conveyors

| Technology | Reliability |

|---|---|

| Scale or metal detector integration | Stainless steel drive components and bearings |

| Premium belting | Non-hollow design with continuous non-porous welds |

| VFD or servo driven for precision motion control | Full washdown ready |

| Controls to support divert, reject, traffic copping | Gearbox and bearing guard package |

Auger/ScreW CONVEYORS

Our custom auger/screw conveyors are designed to handle various food processing needs with precision and efficiency. These conveyors are ideal for moving bulk materials smoothly and consistently, ensuring optimal flow and reducing downtime.

At a glance: Auger/Screw Conveyors

| Technology | Reliability |

|---|---|

| Load Cell and hoppers incorporated | Fully welded and polished or stitch welded flights |

| Augers form 4" to 18" diameter | Hanger bearing free to 30 feet length |

| Full encapsulated or hinged covers | Wear strips or shaped trough |

| Ceiling hung or leg mounted | Stainless Steel drive components and bearings |

KEY FEATURES

Versatile Auger Sizes

Available in diameters ranging from 4” to 18”, accommodating different volume requirements.

Robust Construction

Fully welded and polished flights ensure durability and hygiene, while stitch welding is available for less demanding applications.

Flexible Installation

Can be ceiling hung or leg mounted to fit your facility's layout.

Innovative Design

Incorporates load cells and hoppers for precise weight measurement and material control.

Maintenance-Friendly

Hanger bearing free up to 30 feet in length, reducing maintenance needs and increasing operational uptime.

Custom Covers

Choose from fully encapsulated or hinged covers for added protection and easy access.

Enhanced Durability

Wear strips or shaped troughs extend the lifespan of the conveyor.

High-Quality Components

Stainless steel drive components and bearings for reliability and long service life.

Additional Options

Slide gates and center hung bearing free designs available for specialized applications.

Vibratory Conveyors

Our vibratory conveyors are engineered to move products efficiently while minimizing damage and maintaining product integrity. Perfect for delicate and precise applications in the food processing industry.

At a glance: Vibratory Conveyors

| Technology | Reliability |

|---|---|

| Optimal product handling: reduce loss and/or degradation of product | Low maintenance and designed for sanitation |

| Improved handling for spreading, screening, and laning | Versatile installation options |

| Ideal for scale feeding, product settling, or de-watering | Low cost of operation |

KEY FEATURES

Damage-Free Product Handling

Gentle vibration ensures minimal product breakage and optimal flow.

Quality Components

Stainless steel drive components and bearings ensure reliability.

Flexible Mounting

Options for ceiling hung or leg-mounted installations.

Durable Build

Fully welded and polished or stitch welded flights, tailored to your specific needs.

Multi-Stage Vibratory Conveyor

Vibratory settling can help get 10 lbs of material in a 5 lb bag or container. From belting shakers for alignment, topping settling or troughing shaker conveyors for gentle product handling with no yield loss, vibration may be just the solution.

At a glance: Multi-Stage Vibratory Conveyors

| Technology | Reliability |

|---|---|

| Sanitary vibrators are highly hygienic | Integrates to counters, positioning & packing |

| Reduces product damage and yield loss | UL controls and components |

| Motion control at start/stop/fill/settle level | Stainless steel drive and bearings |

| Integrates to scaling, filling, settling | Proven, robust components |

| Gain filling process efficiencies |

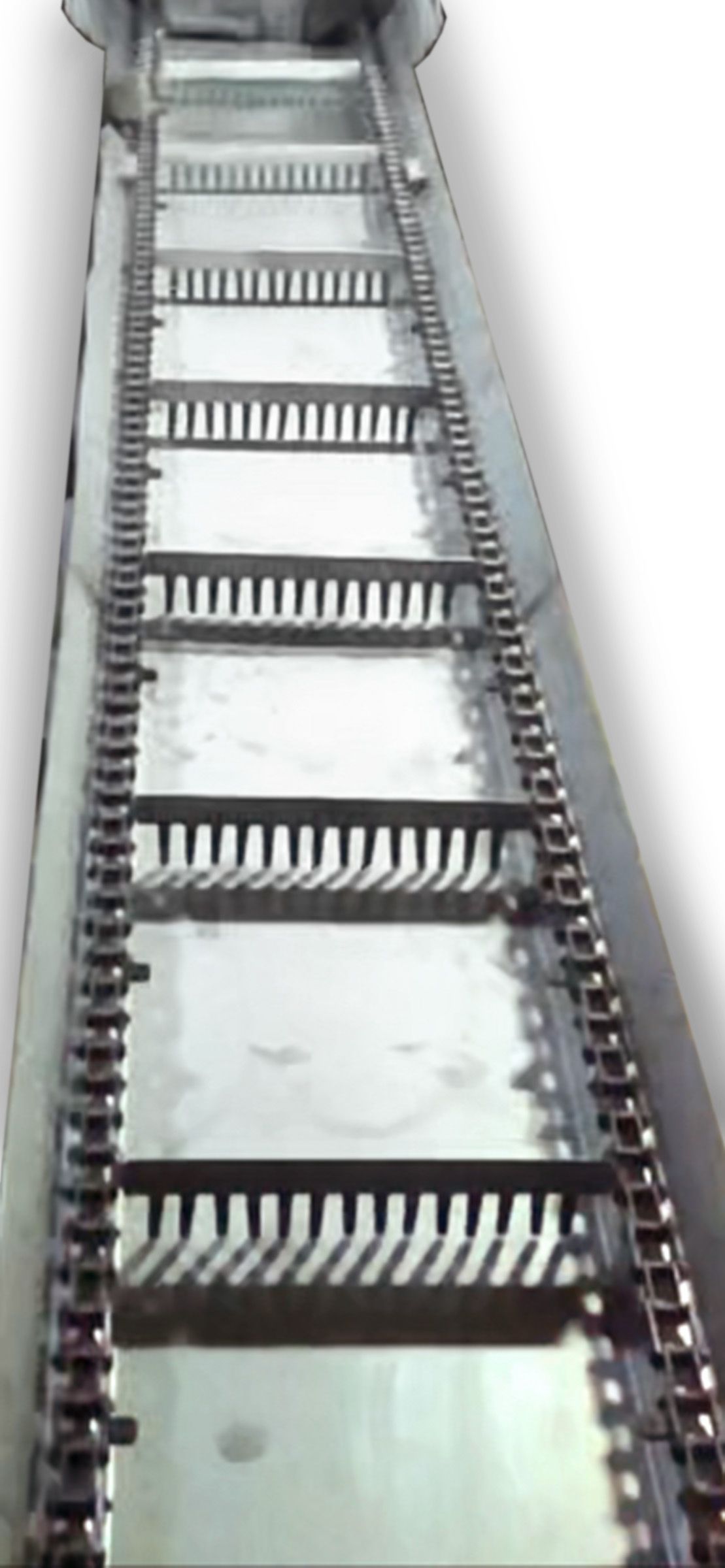

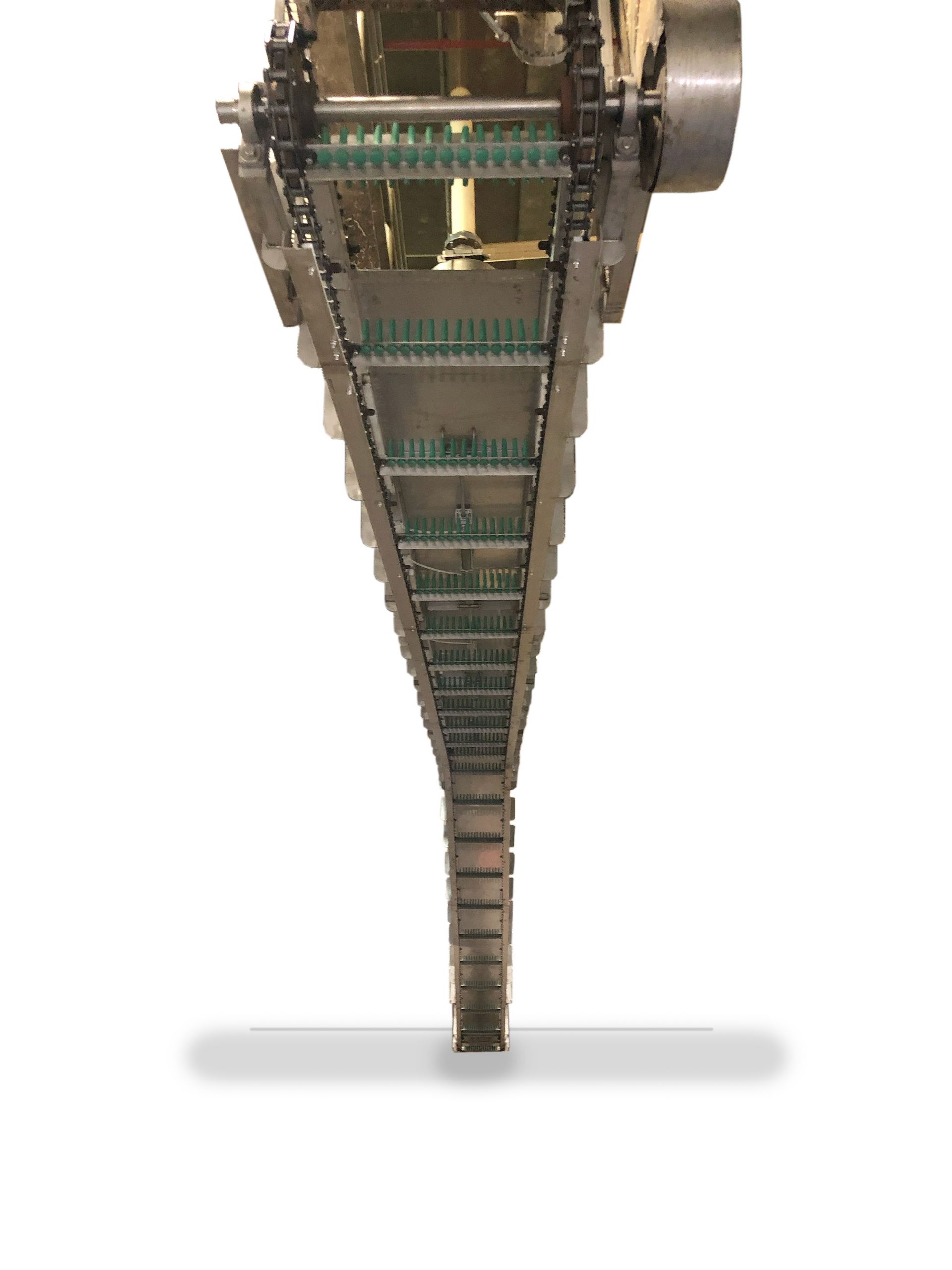

Drag Chain Conveyors

Our drag chain conveyors are designed for heavy-duty applications, providing reliable and efficient material transport in food processing environments. With specialized designs for specific processing needs, these conveyors ensure seamless operation and high performance.

At a glance: Drag Chain Conveyors

| Technology | Reliability |

|---|---|

| Multiple bottom discharge points | Versatile installation options |

| Steep incline handling | Fully welded and polished |

| Performs well with wide range of product sizes | Double roller chains provide a robust structure |

KEY FEATURES

Heavy-Duty Performance

Suitable for transporting bulk materials with ease.

Precision Control

Incorporates load cells and hoppers for accurate material handling.

Protection and Durability

Wear strips or shaped troughs enhance conveyor longevity.

Versatile Installation

Ceiling hung or leg-mounted options to fit your facility’s needs.

Sturdy Construction

Fully welded and polished or stitch welded flights for durability.

Reliable Components

Stainless steel drive components and bearings ensure long-term performance.

Specialized Designs:

Feather Drag

Optimized for light, fluffy materials ensuring gentle handling and transport.

Pit Drag

Designed for below-ground installations, perfect for handling materials from pit areas.

Top Water Skimmers

Ideal for removing floating debris and contaminants from water surfaces, ensuring clean and efficient processing.

Reach Out to Us →

Our custom conveyors are built to meet the rigorous demands of the food processing industry, ensuring reliable, efficient, and hygienic material handling. Contact us today to learn more about how our custom conveyor solutions can optimize your processing operations.